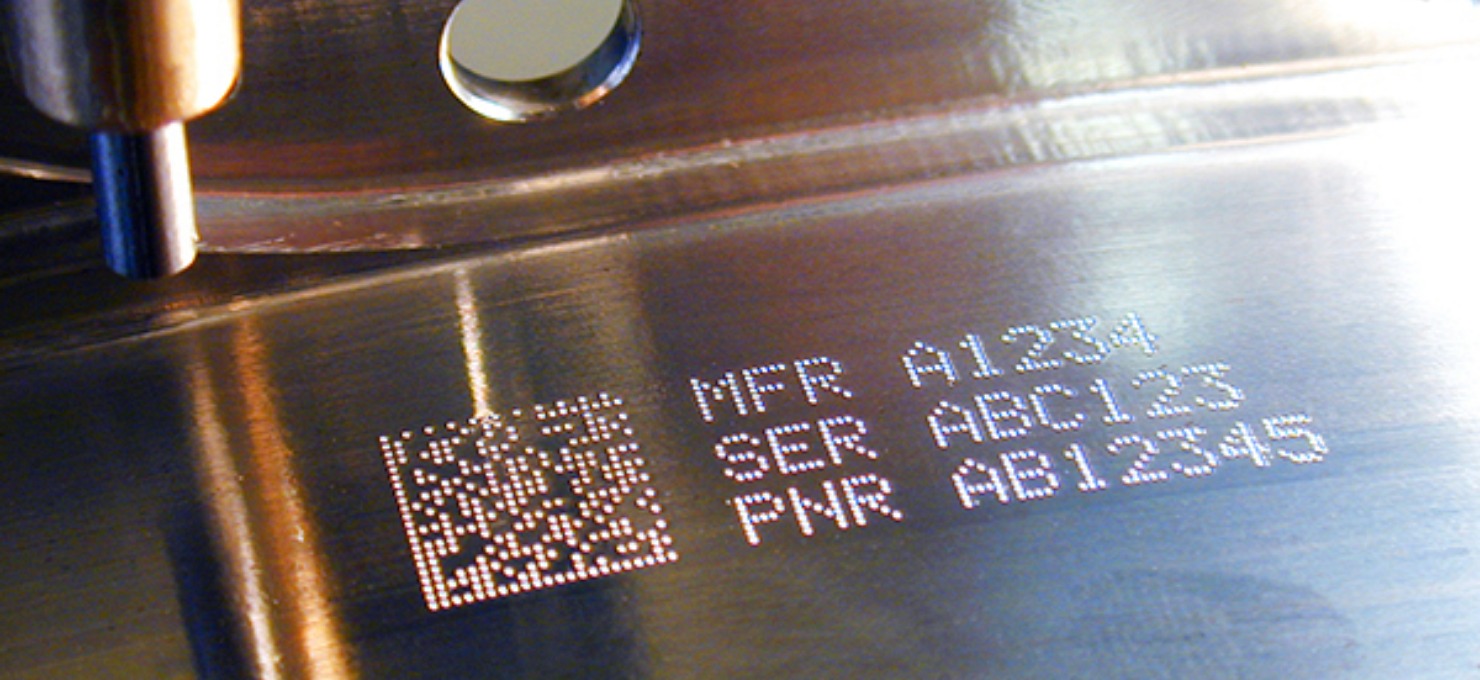

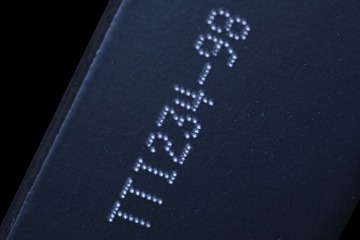

A dot peen marking machine is a type of marking system that uses a pneumatically or electromechanically driven stylus to create indented marks on a surface. The stylus, or pin, rapidly and precisely strikes the material, forming a series of dots to create alphanumeric characters, symbols, or other markings. The term "dot peen" refers to the process of marking by forming individual dots.

Today's manufacturing and customer demands requires the need for the permanent marking. Whether it is a serial number, part number, 2D data matrix code, QR code, logo or other product information, the codes should be impossible to remove, whether deliberately or accidently through use. These codes can be required by law, safety regulations, or product traceability of the manufacturer and even accreditation. Sometimes, it can just make good business sense to have parts clearly, professionally and permanently marked for integrity.

Key features of dot peen marking machines include:

Precision: Dot peen marking provides precise and durable marks on various materials, including metals, plastics, and some composites.

Speed: The process is relatively fast, making dot peen marking suitable for high-volume production environments.

Versatility: Dot peen machines can be used to mark a variety of information, such as serial numbers, date codes, logos, and part numbers.

Durability: The indented marks created by dot peen marking are generally durable and resistant to wear, making them suitable for applications where longevity is important.

Non-Contact: Dot peen marking is a non-contact method, meaning that the stylus does not engrave or cut into the material. This is advantageous for certain materials and applications.